Vortex is a powerful and flexible package. With up to 12 channels for gas, including up to 3 for fire, Vortex can be customized to suit your needs, no matter how complex, and all without the hassle of wiring. Vortex offers all of these benefits while still being easy to deploy and maintain.

Easy to use

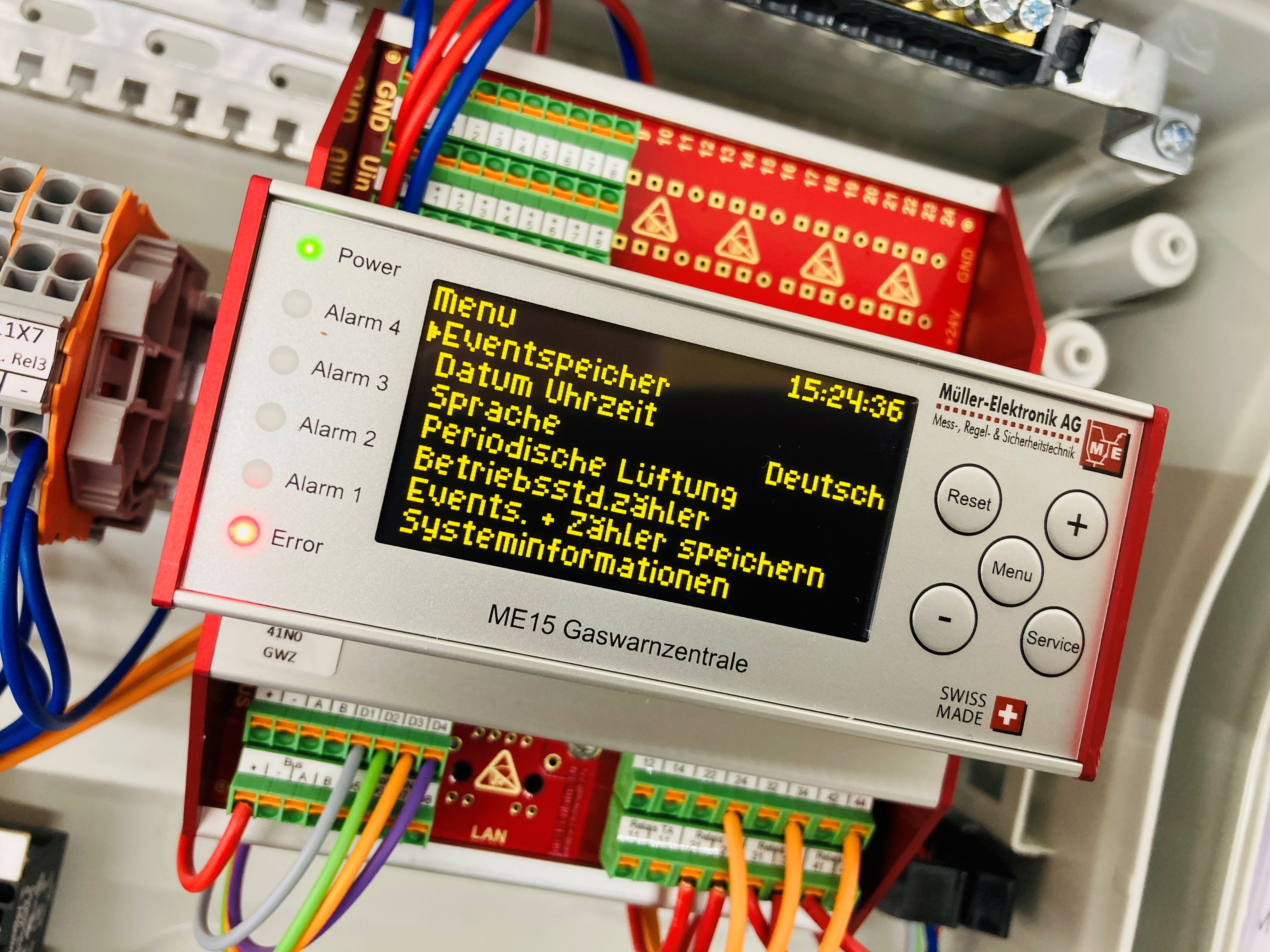

- Vortex offers all the flexibility you need while still being easy to use. All actions to be carried out daily can be done via push buttons on the operator panel.

- The display shows the fault and alarm values for all channels, but the LED only lights up when a hazard or fault is detected. In this way, the entire system can be checked at a glance.

- Even if the alarm or channel settings need to be changed, these adjustments can be made from the outside of the case without the need for additional tools.

Robust and reliable

- You can rely on Vortex because the device has been tested to the most stringent standards. In terms of dust and water ingress, it has been rated IP65.

- Not only does it comply with all current legal requirements, but it also meets the latest gas detection EMC standards.

- For your safety, all relays are continuously monitored: coil failures are identified immediately, ensuring system integrity.

- A power outage is not a problem as Vortex has its own internal backup battery that is constantly monitored for connection integrity and charge level.

- Vortex has been tested according to the functional safety standard IEC 61508 (SIL 1).

Most flexible

- Vortex can be configured to meet all the needs of your facility with a bare minimum of wiring.

- Each channel has 1 fault and 3 alarm levels that can be combined in any way: triggering up to a maximum of 32 output relays.

- Customization is easy. The settings can be pre-programmed from the factory and can be changed at any time using a PC and the Vortex PC software. This means that even extensive systems can be configured without the need for complex cabling.

- Vortex uses industry standard communication interfaces, so it can be easily integrated into your existing control systems.

Simple maintenance

- Vortex was specifically designed to make service and maintenance easy and convenient.

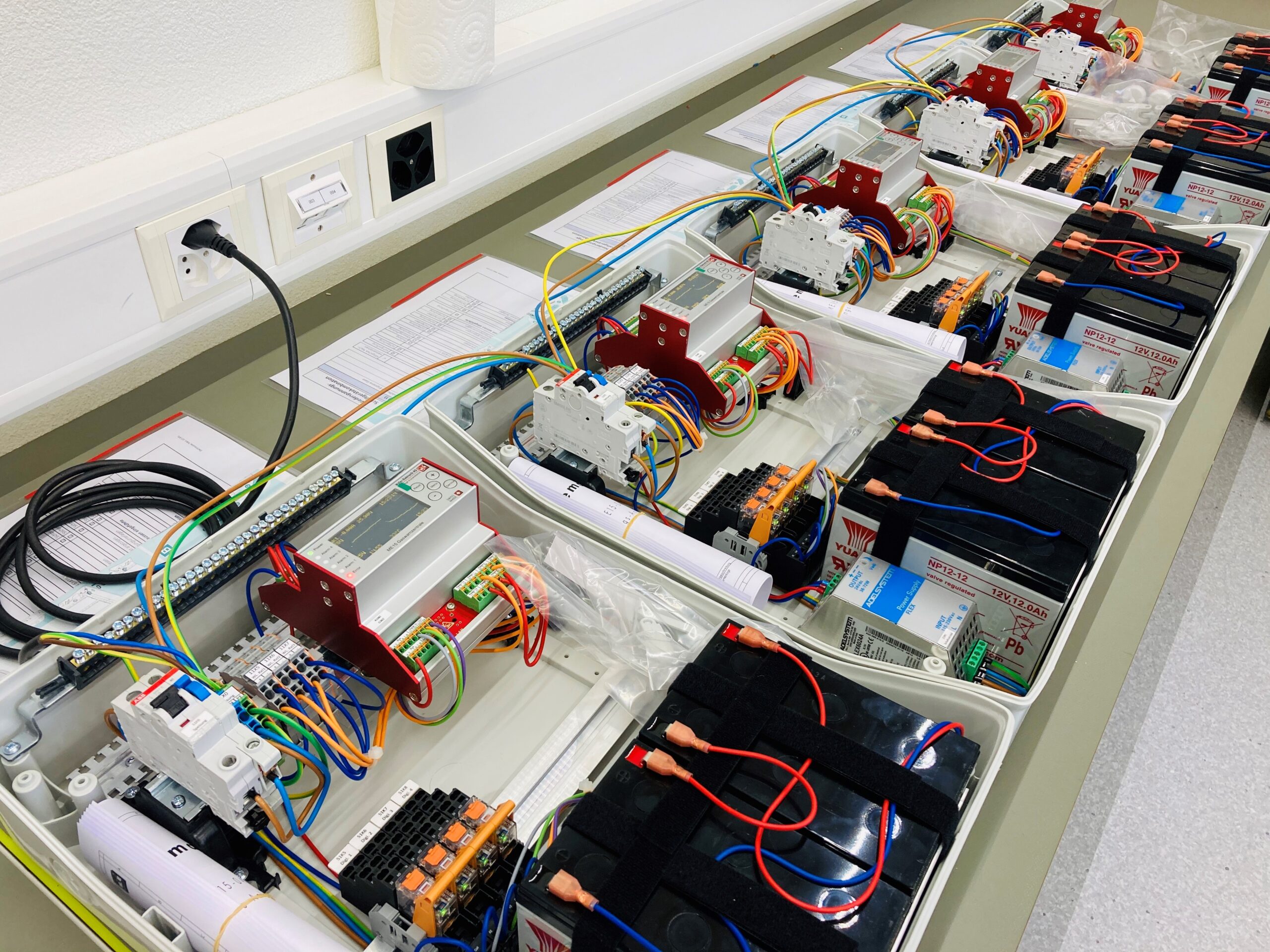

- The modular design means that spare parts can simply be added.

- The space within the housing was designed as large as possible to make the wiring as easy as possible.

- Each zone can be blocked separately, allowing you to work in a specific area without affecting the rest of the system.

- All adjustments are carried out electronically; this eliminated the drift problem with adjustable potentiometers and reduces maintenance to a minimum.

System options

In addition to the standard wall mount console, Vortex is also available in modular and hazardous location certified versions. The Vortex Rack comes with a standard 19” display console and input/output modules, power supply unit and batteries that can be fitted in any 19” rack. Vortex Panel is designed to be mounted in a door or in a console. Vortex FP is ATEX certified for use in Zone 1 or Zone 2 hazardous locations such as: B. on oil production ships and in industrial gauge shelters.